Hermle: A German hidden Champion built to last

A 40% ROIC business trading at historically cheap multiples

The Maschinenfabrik Berthold Hermle AG (Hermle in short) was founded in 1938 by Berthold Hermle as a bolt and machine screw manufacturing company in my beautiful birth state of Baden-Würrtemberg in Southern Germany. Since its founding, Hermle has stood for high-quality products and customer focus.

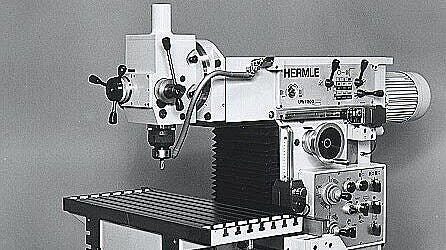

In 1957, the company diversified into producing milling machines and, in 1972, presented the first Hermle universal milling machine. 1978 marked the introduction of Hermle’s first CNC milling machine, the niche they still operate in today and which accounts for most of the business. CNC stands for computer numerical control and marks the beginning of programming and automating the milling process. Nowadays, components are designed using a CAD program from companies like Autodesk or Nemetschek, which runs on the CNC machine.

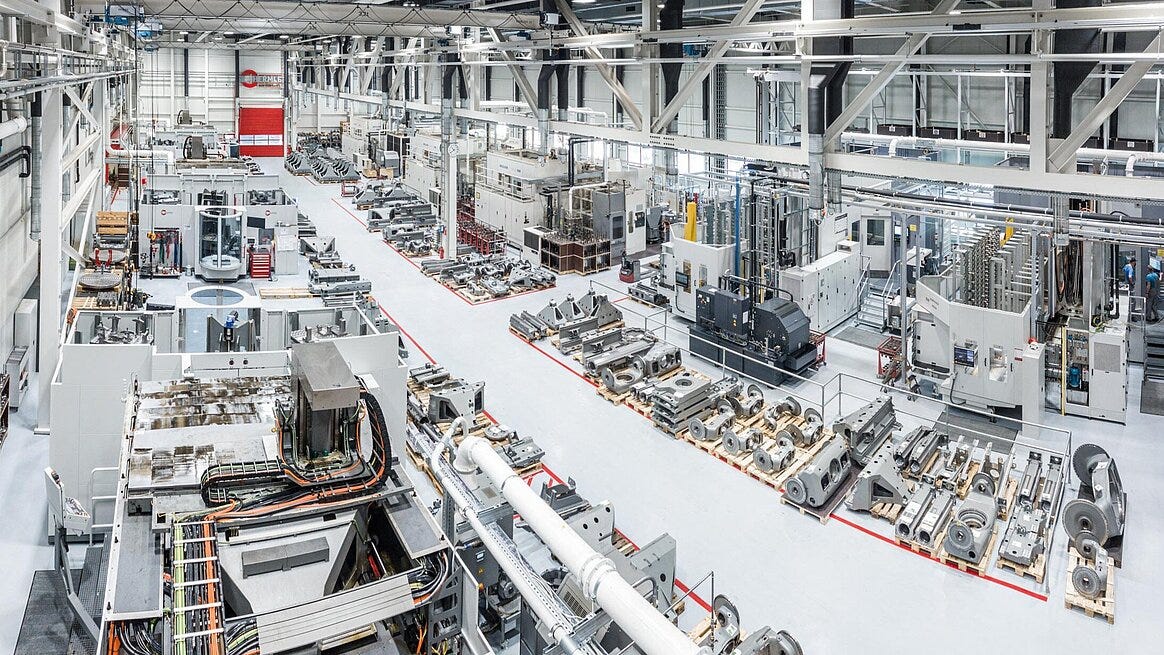

In 1990, the company converted to its current form and IPOed to open a new sales and administration building in Gosheim, its home city. In 1998, the Hermle Systemtechnik GmbH was founded, a joint venture focused on customer-specific automation solutions for Hermle machines. This is the second segment Hermle operates today. The company continued to expand into new geographies worldwide and expand its manufacturing, all within Germany. Today, Hermle generates 534 million euros in revenue, employs 1,511 people and is still family-owned.

Business Model

Hermle is specialized in CNC milling machines, especially 5-axis machines. The company sells in two categories: performance line and high-performance line, depending on the customer requirements. Besides selling the machines, Hermle also sells spare parts for all models they ever sold. This commitment to rigorous, long-term customer focus resembles throughout the organization. The company has over 30,000 machines installed worldwide with a fully decentralized servicing network. Hermle also helps customers design customized automation solutions around the workflows with its machines. Besides that, Hermle has no pet projects but focuses on its core business. The company generates 37% of sales in Germany and the rest internationally, with over 90% coming from selling its machines and spare parts and the remaining from servicing and training. Steel milling is a high-precision business, so naturally, Hermle serves end markets that need high precision and reliability, such as aerospace components, medical devices, or semiconductor manufacturing. Some research companies expect the 5-axis CNC machine market to grow at a 6% CAGR through 2030, while others expect a 10% CAGR. Regardless of the exact amount, the need for automation in light of labor shortages and improving workflows will drive growth for Hermle’s niche.